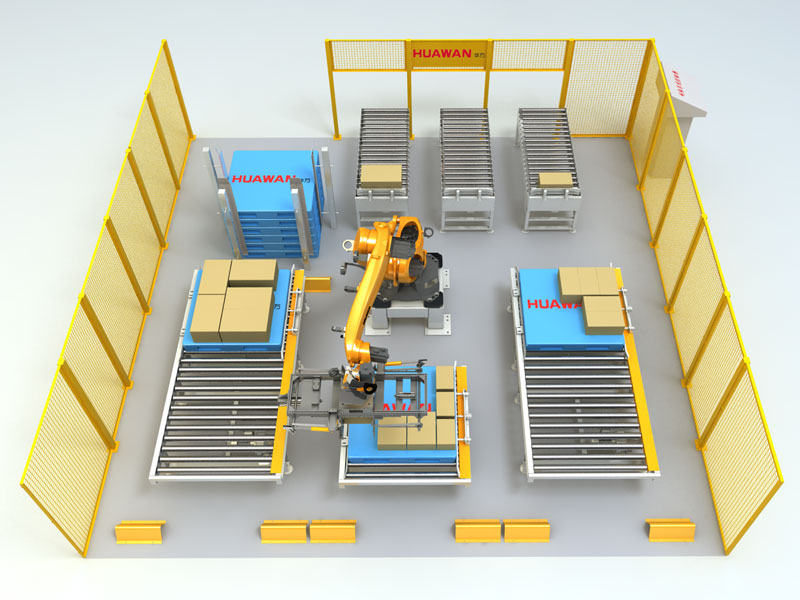

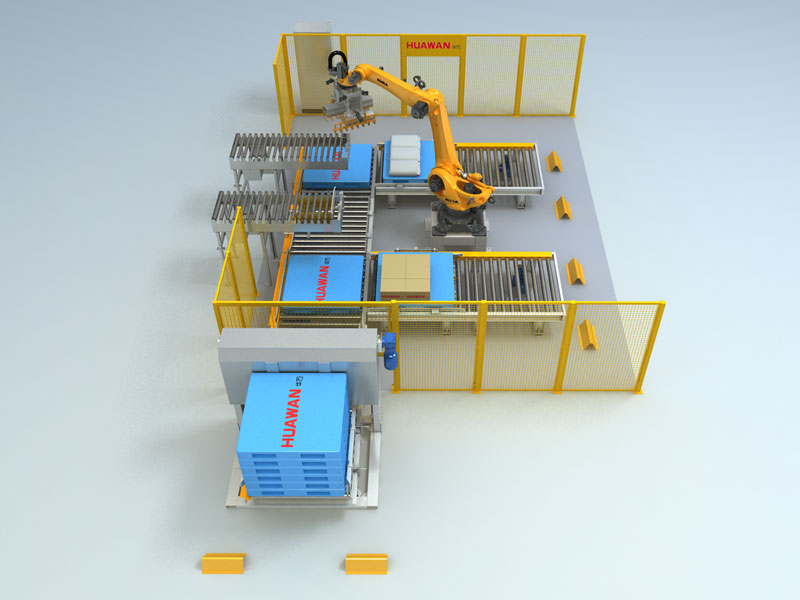

Product classification: Low speed robot palletizing module

Product material: Carbon Steel Paint

Product type: HW120-Z1

Product specification: Can be customized according to customer's needs

Main Technical Parameters

- Feeding transfer speed: 17.5m/min

- Feed line width: effffective width 650mm

- Scope of application: L200-550mm*W200~460mm*H150~450mm

- Applicable tray: L800~1200mm*W800~1200mm

- Stacking roller line height: 400~450mm

- Power supply: 380V 50Hz

- Line height of stacking roller:400-450mm

- Consumption function: to be determined

- Effffective width of the stacking roller line: 1250mm

- The length of the feeding drum line: 2000mm

- General palletizing height: within 1800mm

- Inlet drum height: 650~850mm

- Palletizing capacity: 400~720 cases, 25Kgs or less

- Robot grab head tentative two models, splint type. Splint material: alloy material, not easy to deform.

System components include:

|

Serial number

|

Equipment name

|

Quantity

|

Technical parameters

|

|

1

|

Feed conveyor

|

1

|

2 meters,carbon steel paint side,bracket

|

|

2

|

Robot

|

1

|

KUKA, Germany: KR120R3200PA

|

|

3

|

Gripper

|

1 box

|

Cartons:plywood mode + grab tray

|

|

4

|

Robot base

|

1

|

Height to be determined, carbon steel paint

|

|

5

|

Palletizing station

|

1

|

Length 1.5 meters, width 1.25 meters.Carbon steel plastic spraying

paint rack.

|

|

6

|

Stacking position

|

1

|

Length 1.5 meters, width 1.25 meters.Carbon steel plastic spraying

paint rack.

|

|

7

|

Safety net

|

1 set

|

Carbon steel spray paint (palletizing area)

|

|

8

|

Control system

|

1 set

|

|

Equipment main components selection

|

Serial number

|

Product name

|

Component maker

|

|

1

|

Button

|

Schneider

|

|

2

|

Proximity switch

|

Thicke

|

|

3

|

Photoelectric switch

|

Thicke

|

|

4

|

Relay

|

Schneider

|

|

5

|

Power switch

|

Schneider

|

|

6

|

PLC

|

Siemens 1200 series

|

|

7

|

Inverter

|

Schneider

|

|

8

|

Pneumatic components

|

Faustus

|

|

9

|

Power element

|

SEW

|

|

10

|

Touch screen

|

Siemens

|